Ossid Weigh Price Labelers Help Iowa Pork Producer Meet Current and Future Growth

A subsidiary of Perdue Farms (www.perduefarms.com), Perdue Premium Meat Company (PPMC) is a full-service facility that produces a variety of pork products in Iowa. The company is an industry leader offering all-natural, no antibiotics, pasture-raised pork raised by independent family farmers across the United States. In 2020, the company completed a $29 million expansion of its Sioux Center facility that added more than 50,000 square feet of space to accommodate upgraded equipment, revamped processing and packaging lines for case-ready production, and other enhanced employee safety and wellness programs.

PPMC operates on 100% wind power and uses a closed-loop wastewater system that filters and recycles the water to provide nutrients to surrounding farmland. The plant is certified humane and incorporates several practices that exceed industry standards, including live video feed monitored by a third party.

To meet increased demand for its pork products, PPMC upgraded its packaging equipment, a change that necessitated faster weigh price labelers. The company gave its current labeling vendor the first opportunity to supply equipment, but its performance could not keep pace with the high rate of speed it was looking for.

“We were adding larger packaging machines, and we needed our labelers to hit those higher speeds to match the output we were looking to obtain,” said Jon Schelling, Director of Case Ready Operations & Purchasing, PPMC. “So, the question became how do we reach those speeds and do so in a confined footprint? We needed a weigh price labeler system to not only keep up with today’s production rate, but to grow with us in the future.

“The look of the package is top 3 as far as importance for what we do. We are a niche market, pasture-raised, no-antibiotic pork. With that comes a premium on the price. So, when you’re asking a customer as these higher end retailers to pay more for a product and if you have something in the shelf that doesn’t look good, labels crooked, you can’t read the print, the customer is going to look at that and say that isn’t a premium product, I’m not going to pay a premium price.”

Ossid (www.ossid.com) is well known throughout Perdue Farms, as other divisions rely on the brand for weigh price labeling. After the first supplier fell out of contention, PPMC turned to Ossid, a North Carolina-based food packaging OEM of weigh price labeling systems, as well as tray overwrapping, thermoforming, vacuum skin, and other packaging solutions. Ossid is part of ProMach, a company of 47 product brands that operate across the entire packaging spectrum.

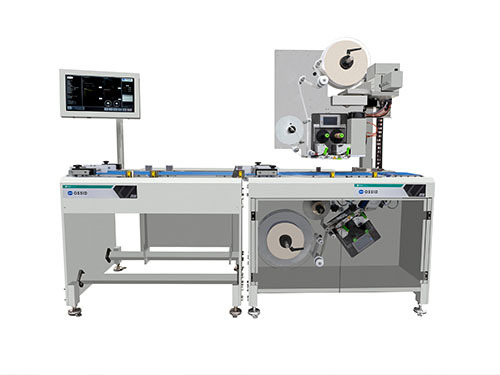

After reviewing the application with PPMC, Ossid recommended two NextGen 2115 Weigh Price Labelers, which can handle up to 150 packages per minute each. Utilizing WYSIWYG label design, the weigh price labeler has an interface that allows the end user to view a projected model of the label while it is being created. Furthermore, the machine is modular in design, allowing for short lead and delivery time, and is National Type Evaluation Program (NTEP) approved.

“We approach our projects from a point of honesty and open communication. So, we sit down, listen to the current struggles and where you want to go and we work together to partner to get to that point, said Jared Rangel, sales representative, Ossid. “When you run a variety of different products, automation can be difficult. So, you need a partner in the industry that’s willing to work together with you to create a solution that will work across the whole gambit of products that you might run.”

Ossid's Weigh Price Labelers can handle trayed, shrink, and thermoform packages. Perdue Premium Meats also uses thermoformed saddle pack style for some products that require two labels to be applied to both sides of the package – a challenging application easily performed by Ossid's weigh price labeling machines. Furthermore, the stainless steel construction is perfect for harsh production environments of the protein industry, and the open frame design provides great access for cleaning.

The two weigh price labelers were installed in February and August of 2023, respectively. PPMC operates one shift a day; the two packaging lines run on between two and three days a week. The thermoformer line packages just under 3,000 pounds per hour. Types of products PPMC is packaging include an assortment of pork offerings, such as three-pack boneless chops, two-pack bone-in chops, 1-pound brick of ground pork, and direct-to-consumer selections.

“If we’re asking a premium price for our cuts, we need to produce a premium package, and our Ossid weigh price labelers help us do that,” Schelling said. “Our equipment has done everything we were sold on, and the technical support that Ossid offers has been fantastic.

“From a production standpoint, our new Ossid machines are giving us higher output; we’re not missing a beat. We can package more pounds per day without having to add more hours in the week, which is saving us money through efficient operation. Working with Ossid has been a pleasant experience.”

Ossid’s NextGen 2115 Weigh Price Labeler Helps Boost Perdue Pork’s Efficiency